Most of the problems with 12v water pumps lie with the fact that water hates being moved. Here are some ways to reduce the noise and get longer life from your pump:

How best to set up your 12 volt water pump system?

Don’t over-tighten the screws on the base of your pump. Over-tightening the pump’s attachment screws compresses the rubber mountings, hindering their ability to absorb sound energy. A new addition to the Escaping Outdoors range of FL water pumps is the metal base plate for added stability. These cost a little more to buy but we have received excellent feedback on the base plate options.

- Have a truly rigid mounting base. If you knock on the proposed base and it responds like a drum, it’s going to worsen pump noise. Another effective solution is to place a small piece of carpet between the pump and its base.

- Use the thinnest hold-down screws that will adequately hold the pump.

- Use flexible piping. It is surprisingly effective at dampening sound - try including about 350 mm of truly flexible piping between in a very loose loop between the pump and any hard plumbing on the pump inlet and outlet. If they are unable to move freely a lot of noise will be transmitted via these pipes. The difference in transmitted noise is so great that it can be worthwhile connecting each pipe using a full loop.

- Avoid elbow fittings close to the outlet port. They cause turbulent water flow and also back pressure – both of which generate noise. Use smooth curves rather than right angle bends.

- Prevent vibration in the wall cavity. Another cause of transmitted noise including water hammer is vibration where plumbing passes through a wall. During installation ensure the pipes are unable to move especially where they go through a wall. Use plastic foam or insulation to keep them in place.

Do you have air in your 12 volt pump system?

Trapped air causes plumbing to rattle and is one of the main causes of pump failure of any brand of pump. It is desirable to bleed all air from the system to prevent this.

Check all joins and connections to make sure no air is entering your pump. If air gets into the pump it will cause cavitation and the pump will continue to run. The pumps motor will eventually burn out if the pressure switch doesn't fail first in order to protect the pump.

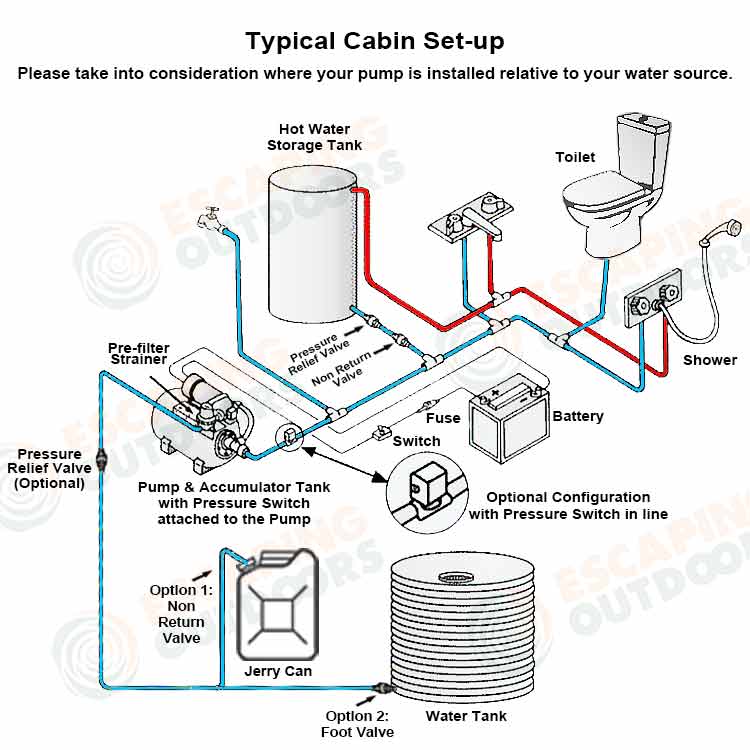

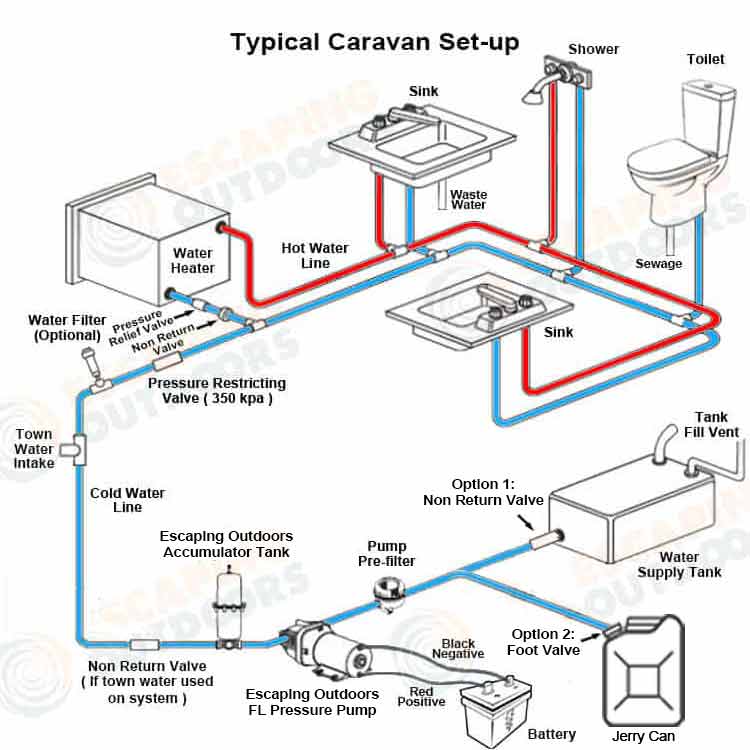

Do I need a check valve, foot valve or non-return valve for my 12 volt pump system?

Dependant on your water supply, when setting up diaphragm pumps you need to place a valve between the water supply and the pump. This is a very important part of your pump set up in a caravan style situation. The valve is used to keep the pump primed and must be installed in the correct position. Without the valve, the pump will sense a drop in pressure if water siphons back to the water supply creating an air pocket in your system. The pump will also turn on and keep pumping air without the pump switching off until it eventually overheats and cooks the motor.

There are two types of valves to choose from:

- A check valve ( foot valve ): use if using a jerry can style of water supply with a hose going into the can or container. The check valve goes on the end of your pipe / hose if the pump is mounted higher than your water source.

- A non-return valve: if using a closed container with an outlet. The non-return valve connects to the bottom of the water tanks outlet. If the water source is equal or lower than your pump, the non-return valve prevents water draining back to the water source and creating air pockets which can cause damage to your pump.

Do you have water cycling or water hammer with your 12 volt water pump?

Add an accumulator tank. This will dramatically reduce the noise, pulsation, pump circulation and will extend the life of your pump. The result is a smooth and quiet stream of water.

Refer to our article on "Do I need a pressure tank or accumulator tank" on my 12 volt water pump system. This article will help you to understand why most 12 volt water pumps on the market are best used with a pressure tank in their system and why some pumps "Smart Pumps" have variable speed and a built in by-pass so don't generally need one with their advanced technology. These "Smart Pumps" are generally a much dearer option to purchase making the cheaper pumps with an accumulator tank added to the system a good affordable option for many Aussies. Does the pressure switch need replacing often on your 12 volt water pump

Add an accumulator tank to your 12 volt pump setup. Your pressure switch is your pumps first line of defence when there is something not right in the setup, there is an air leak or an inbalance of pressure in your system. The pressure switch will fail first to stop the pump operating to protect the pumps motor.

If your 12 volt water pump stops working the first thing to check is if it is the pressure switch or the pump itself. It is a simple process to bypass the pressure switch to check this. Here is a link to test if your pressure switch has failed on your 12 volt water pump.

If you follow these steps you will have a pump which makes no more noise than a good sewing machine. Truly!

We're here to help so if you require help in your decision making when purchasing a 12 volt water pump or in how to best set up your pump for your caravan, bus, campervan, food cart etc please drop us a line or give us a call on 1300 411 366.

Water Pumps Now Your Online Pump Shop

Water Pumps Now Your Online Pump Shop