When dealing with the treatment of wastewater whether it is a domestic sewage situation, a council or municipal toilet block or the full sewage and wastewater systems of towns and cities, the use of “flushable” wipes, sanitary items and a huge range of objects which are now flushed, need to be dealt with.

Why do we need Cutter Pumps or Grinder Pumps?

The changing composition of today’s wipes, rags, greases and other materials tend to rope together forming large masses that wind themselves into clots of fibrous rags as in the attached photo. These rags then can bind around impellers or plug before a suction making it impossible for them to pass through a wastewater or sewage design that may have worked successfully for generations. For this reason the increase in clogging problems means non-clog pumps are no longer the solution in most cases. It is necessary to reduce the size of the solids entering the pump through some form of chopping, cutting or grinding. This has meant a huge shift to Cutting Pumps and Grinder Pumps for sewage and wastewater.

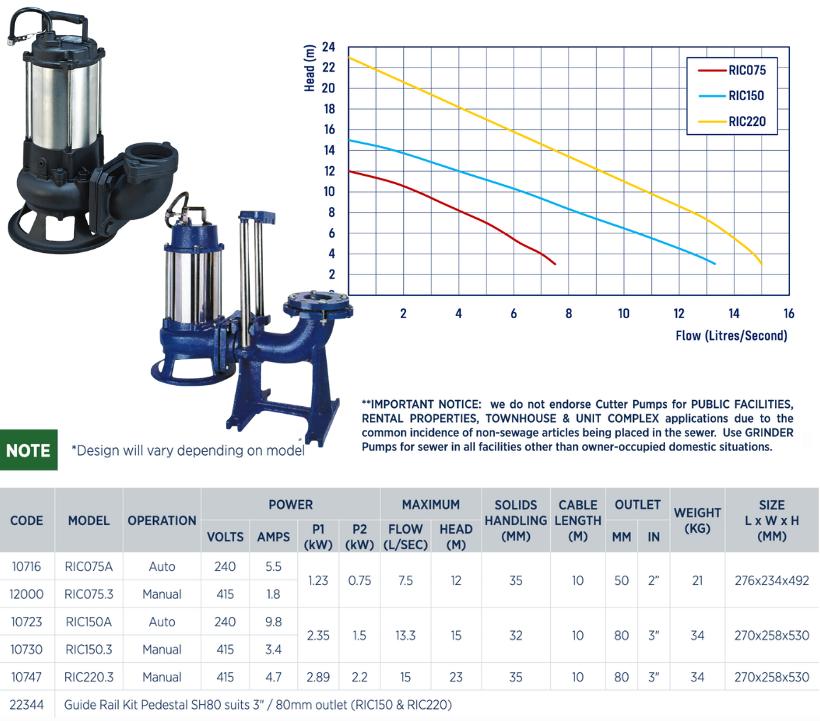

The design of Cutter pumps is to reduce the size of solids in the wastewater or sewage system. Cutter pumps are used to cut and pump trade waste, mining and quarry waste, treated waste, effluent, sewage and submersible cutter pumps are also used for farm waste.

The impeller of the cutter pump drives the rotating cutting action while the stationary element is mounted at the pump’s suction inlet. The cutter on the pump is stationary with a ring with cutting teeth that shred any materials which enter the pump.

Energy efficient, there is a good range of submersible Cutter pumps with different heads and flows to suit most applications.

Do Cutter Pumps come in Automatic models?

Submersible cutter pumps come in automatic and manual models and are often used in Pump Stations. If you require a submersible cutter pump for a pump station please contact us to discuss your specific custom requirements so we can quote you with a setup just for you.

Submersible Sewage Cutter pumps are ideal for owner occupier domestic situations. We do not endorse cutter pumps for Public Facilities or Rental applications due to the common incidents of non- sewage “flushable” items being placed in the sewer.

What are the benefits of a Grinder Pump?

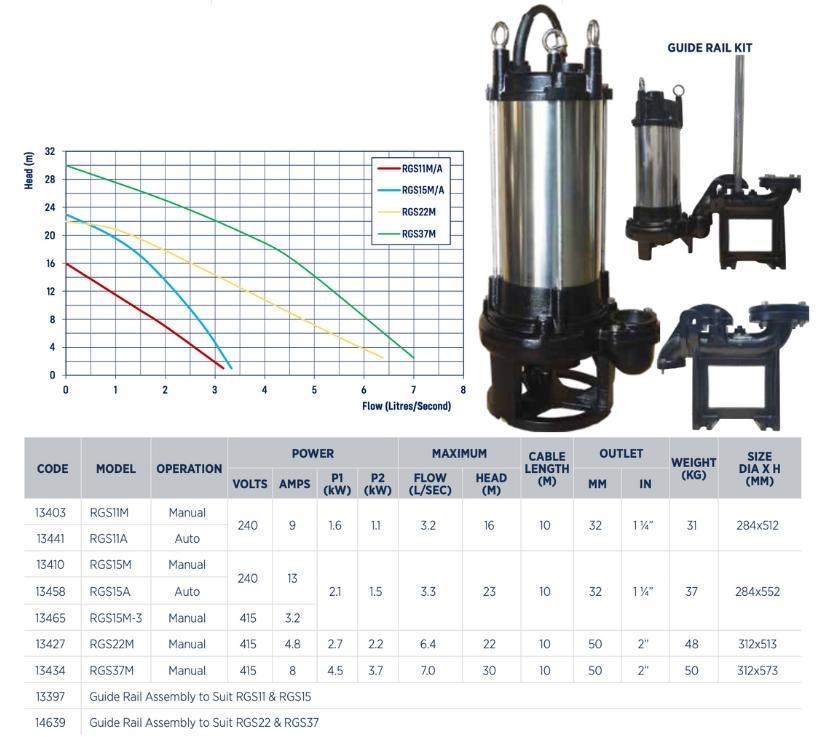

Submersible sewage Grinder pumps and wastewater Grinder Pumps are used for the most demanding industrial and commercial applications.

Grinder pumps use an impeller designed with a rotating cutting device that macerates materials at the pump inlet turning it into a fine slurry. This pump type is typically is found in lower-flow applications.

Most Grinder pumps are heavy duty industrial submersible pumps which are run at higher speeds and installed at the source of the supply to the main sewage system.

Our Grinder pumps at Water Pumps Now Australia come in either 240v or 415v (3 phase) with superior engineering. The mechanism of the grinder is very powerful with in excess of 80,000 slicing actions per minute. The radial cutter and the cutter ring decreases the torque and kilowatt requirements and this in turn ensures these grinder pumps are one of the most effective grinder pumps on the Australian pump market.

Grinder pumps are used extensively in commercial buildings, hotels, hospitals, nursing homes, municipal toilet blocks, childcare facilities and other public places.

Which size or model Grinder pump or Cutter pump, do I choose?

If you are unsure of which grinder or cutter pump to choose please contact us with details of the application for the sewage pump or waste water pump and one of our highly qualified technical advisors will be happy to help.